Exhaust air purification refers to the process of removing harmful or undesirable substances from the air that are produced during industrial, commercial or other technical processes. The aim is to improve the quality of the exhaust air so that it has no adverse effects on health or the environment and complies with the statutory emission limits. To this end, we use state-of-the-art technologies, such as catalytic processes, sometimes in combination with adsorption or UV purification, depending on the type and concentration of the pollutants and the specific requirements of the respective application.

As a provider of industrial exhaust air purification, we understand the challenges companies face in complying with strict legal requirements for air quality. Our exhaust air purification solutions help companies to treat their exhaust gases efficiently and reliably comply with the specified limits for pollutants, dust, odours and aerosols. With our advanced technologies, we ensure a significant reduction in emissions and help companies to meet their legal obligations while making an important contribution to environmental protection.

Contact experts in industrial exhaust air purification and get advice

- Challenges and solutions at a glance

- How do we solve the problem of industrial exhaust air purification?

- Reducing emissions in practice: How it works!

- Industrial exhaust air purification: What requirements must industrial exhaust air purification systems meet?

- Difference between exhaust gas and exhaust air

- Why is industrial exhaust air purification so important?

a. Compliance with legal emission limits

b. Energy saving and economic efficiency

c. Durability in continuous operation - Diverse challenges: Examples of different types of industrial exhaust air

- Exhaust air purification in the chemical industry: How chemical companies are overcoming their exhaust air challenges

- Exhaust air purification solution for paint shops and coating companies – how modern exhaust air purification increases competitiveness

- Tailor-made exhaust air purification solutions for the printing industry (graphotypography, flexography)

- Exhaust air purification solution for the pharmaceutical industry: Future-proof and audit-compliant – how pharmaceutical companies are meeting environmental regulations

- Odour elimination for roasters and processors: Modern exhaust air purification solutions for the food industry

- Smart exhaust air purification solutions for biogas plants, sewage treatment plants and the waste management industry – why operators of biogas plants, sewage treatment plants and the waste management industry need to act now

- From project launch to continuous operation: Exhaust air purification as a success factor in battery and semiconductor production

- Exhaust air purification for solvents – how to sustainably and efficiently manage solvent emissions in your operations

- xpuris - Exhaust air purification technologies for industry: Which processes are suitable for my needs?

a. CatOx - Catalytic afterburning

b. Adsorption process

c. Ozone treatment - Exhaust air purification systems – tailor-made and unique solutions and processes for industrial exhaust air purification for every exhaust air flow

a. Our responsibility xpuris technology for exhaust air purification is a win-win situation for everyone

b. Discover how tailor-made high-tech solutions can clean your exhaust air – and make your company fit for the future!

c. With these technologies, you are guaranteed clean air and maximum economic efficiency! - Advantages of our services at a glance

- Your way to clean air - we offer these services for you as xpuris regarding exhaust air purification systems

a. Services

b. Mobile test systems - Trust our expertise

Industrial companies face the task of efficiently removing a wide variety of emissions, including dust, odours, aerosols, volatile organic compounds (VOCs) and other pollutants. As a modern provider of industrial exhaust air purification solutions, we meet these challenges with innovative and modular system concepts based on catalysis, adsorption or UV oxidation. Through the targeted selection and combination of these technologies, we flexibly solve industry-specific requirements – whether in the chemical industry, the painting and coating industry, the printing industry, the pharmaceutical industry, food production or battery and semiconductor production.

In order to meet the complex requirements of modern production processes, we rely on individual analysis of exhaust air compositions and process conditions. We select the optimal purification technologies for each application and tailor them precisely to the respective industrial companies and their requirements and processes. Automated measurement and control systems ensure compliance with limit values and continuously document the exhaust air quality. At the same time, heat recovery is used to further increase energy efficiency. Our systems are designed to be integrated into existing processes without major downtime. Regular maintenance, technical support and employee training guarantee trouble-free continuous operation. Comprehensive measurement services and support with regulatory approval procedures round off our range of services. All processes are fully documented for audits and environmental reports.

Contact experts in industrial exhaust air purification and get advice

High-performance exhaust air purification systems can sustainably reduce a wide range of pollutants, including dust, volatile organic compounds (VOCs), solvents and odours. This is made possible by the targeted combination of various filter, adsorption and oxidation processes, which can be optimally combined with each other depending on the pollutant profile. An important component of many modern systems is heat recovery: this involves recovering the energy contained in the exhaust air and using it to optimise production or, in most cases, feeding it back into the raw gas stream, which saves costs and also significantly increases resource efficiency.

A holistic plant design also ensures that secondary emissions are minimised. In many cases, the purified air or energy recovered can thus be fed directly back into the production processes. Permanent emission monitoring and a modern monitoring system ensure compliance with all legal requirements and offer additional safety in daily operation.

In order to achieve optimum emission reduction for you, we provide comprehensive advice on emission management and reporting requirements and use certified procedures with proven efficiency. In this way, we ensure that you meet all legal and company-specific requirements – and can document this reliably.

Find out how you can reduce emissions in a personal consultation

TA Luft (Technical Instructions on Air Quality Control):

Central German regulation for permissible emissions and the technical status of air pollution control.

TA Lärm:

Regulates permissible noise emissions from industrial plants, thereby protecting employees and residents.

Federal Immission Control Act (BImSchG):

Legal basis for preventing harmful environmental impacts caused by air pollution, noise, vibrations and similar phenomena.

VOC Directive (2010/75/EU – IED):

European Directive on the limitation of emissions of volatile organic compounds from industrial installations.

DWA-M 264 (Information sheet on exhaust air purification in industry):

Technical data sheet for exhaust air purification and compliance with limit values in industrial processes.

Explosion protection (ATEX):

European directives on protection against explosions in installations with hazardous gases or dusts.

DIN standards / EN standards

Technical standards to ensure quality and safety, such as:

- DIN EN 12779: Emissions reduction in paint shops.

- DIN EN 14181: Quality assurance of emission measurements.

- DIN EN 1822: Requirements for high-performance particulate filters.

- DIN EN 60079: Explosion protection for electrical installations.

International standards and specifications:

Additional requirements apply in international operations, such as:

- US EPA Clean Air Act (USA): US regulations on air pollution control.

- MACT-Standards (Maximum Achievable Control Technology): Technical specifications for pollutant minimisation in the USA.

BREFs and BAT :

BREFs and BAT ultimately raise the bar even higher for every industrial sector. These EU guidelines describe the best available techniques (BAT) for each sector, and the BREFs (Best Available Techniques Reference Documents) specify the emission limits to be achieved.

Exhaust gas refers to gases produced during industrial processes or technical operations. The oxygen content can vary depending on the exhaust gas. Exhaust air in particular has a normal oxygen content and usually has a lower concentration of pollutants. While typical exhaust gases are mainly produced during combustion processes – for example in engines or power plants – and often contain CO₂, nitrogen oxides (NOₓ), sulphur dioxide (SO₂) or soot, exhaust air from non-combustion processes usually originates from industrial plants and more often contains solvents, dust or organic substances. Since different legal requirements apply to exhaust gases and exhaust air, and different measurement and purification methods are therefore used, a clear differentiation is necessary.

Effective exhaust air purification is essential for companies today because compliance with statutory emission limits is mandatory and it protects employees, the neighbourhood and the environment from health risks. Companies that do not effectively reduce their emissions risk heavy fines and, in the worst case, even the closure of their operations. On the other hand, those who act responsibly and with foresight also contribute to a positive corporate image.

Modern exhaust air purification systems offer enormous potential for reducing energy and operating costs. The use of heat recovery systems can significantly reduce energy consumption. xpuris systems also make it possible to completely eliminate the use of fossil fuels, resulting in sustainably lower operating costs and short payback periods. Investments in efficient technologies are also often supported by national or regional subsidies.

Industrial exhaust air purification systems are designed for years of use in demanding industrial environments. Their robust construction and maintenance-friendly components enable the uncomplicated replacement of wear parts. A secure supply of spare parts and fast repair options also ensure minimal downtime. Our systems are also optimised for particularly low wear and tear, so you benefit from a reliable and efficient solution in the long term.

Exhaust air containing organic compounds (VOCs and solvents):

These arise, for example, during painting, printing or in chemical production processes and can be harmful to both the environment and health. Catalytic processes or adsorption solutions are particularly suitable for these pollutants, as they remove VOCs efficiently.

Gaseous pollutants produced by combustion, such as carbon monoxide (CO), nitrogen oxides (NOx) or sulphur dioxide (SO₂)

Technical data sheet for exhaust air purification and compliance with limit values in industrial processes.

Pollutants from chemical reactions

– including ammonia and chlorine, for example – are often found in the chemical and pharmaceutical industries. Some of these substances are highly reactive or toxic and must be removed in a targeted manner. Special filter and catalyst systems are tailored to the respective pollutant.

Exhaust air from fermentation processes

often contains alcohols or methane, which are produced, for example, in food production, biotechnology or biogas plants. These emissions require individual exhaust air purification systems that combine adsorption or oxidation processes depending on the composition.

Particles, dust and fine dust

Particles, dust and fine dust can also be present in the exhaust air and are produced by mechanical processing, when handling bulk materials or during processes such as grinding and crushing. These dusts can contaminate both the production facilities and the air we breathe. Special filter and separation systems are used here to remove solid particles from the air.

Odours and volatile substances

are particularly relevant in food processing and waste management. UV cleaning or combined filter processes help to effectively neutralise these odours.

Aerosols, mists and vapours

are produced in processes where liquids evaporate or are finely dispersed – for example, in metal processing or cleaning with solvents. Special aerosol separators or adsorption systems ensure the necessary air quality in these cases.

Grease and oil mist

often originate from food production or metalworking processes such as lubrication or cooling. They can cause deposits and are difficult to remove from the air. This is where tailor-made filter solutions and efficient separation systems come into play.

Acidic or alkaline emissions

There are also acidic or alkaline emissions, which occur particularly in chemical production processes or during cleaning and surface treatment. In such cases, special chemically resistant filter systems or scrubber systems are used.

Depending on the industry, production process and location, this results in an individual exhaust air profile – and thus the need to tailor the cleaning solution precisely to it. That is why we work with you to develop a tailor-made exhaust air purification solution that is precisely tailored to your operational requirements and even to complex, multi-stage production processes. This allows you to benefit from efficient, legally compliant and highly economical exhaust air purification that is sustainably tailored to your requirements and your operations.

8. EXHAUST AIR PURIFICATION IN THE CHEMICAL INDUSTRY: HOW CHEMICAL COMPANIES ARE OVERCOMING THEIR EXHAUST AIR CHALLENGES

Chemical companies face particular challenges. Production often generates exhaust air mixtures that may contain toxic, reactive or even explosive substances – frequently in very large volumes. Typical examples include large quantities of volatile organic compounds (VOCs), ammonia (NH₃), nitrogen oxides (NOₓ) and other hazardous pollutants originating from various production areas.

The complexity of exhaust air purification varies depending on the type of product being manufactured, the chemicals used and the production process employed.

- Basic chemicals often result in large quantities of ammonia, nitrogen oxides or acidic gases. The exhaust air purification systems must be particularly powerful, corrosion-resistant and safe in order to reliably remove large quantities of these hazardous substances.

- Plastics and polymer production releases many solvents and volatile organic compounds (VOCs). Even small amounts require extensive cleaning.

- Speciality chemicals can be particularly reactive or explosive. This means that the highest safety requirements must be met for exhaust air purification systems.

- Companies with frequently changing processes (e.g. contract manufacturers or seasonal production) have to deal with constantly changing pollutants. Conventional cleaning systems often reach their limits here.

Legal requirements are making the situation and the demands for exhaust air purification even tougher. TA Luft 2021, the EU Industrial Emissions Directive (IED) and the REACH Regulation set strict limits and require complete documentation of all emissions. This poses a major challenge for companies, operations managers and environmental managers, especially when product changes are frequent, as the composition of emissions is constantly changing and purification processes must be adapted quickly. Failure to comply with the requirements can result in penalties, fines or even the shutdown of plants or even the entire business.

Companies that still use outdated exhaust air systems such as thermal afterburners also consume an unnecessary amount of energy. This leads to permanently increased operating costs and is becoming more and more of an economic disadvantage, especially when energy prices rise and legal requirements become stricter.

If there is no immediate need for action due to the modernisation of production facilities or the necessary reduction of operating costs, this will become apparent at the latest during audits or official inspections. This then requires a rapid response in order to avoid penalties.

Modern, modular exhaust air purification systems enable targeted and reliable reduction of emissions and compliance with all legal and regulatory requirements. Converting to efficient technologies such as UV, adsorption or catalytic systems can achieve significant energy savings, which ensure a fast return on investment thanks to lower gas consumption. The various processes can be flexibly combined to efficiently remove large quantities of VOCs, ammonia, nitrogen oxides and other pollutants. Regardless of whether you manufacture basic chemicals, polymers or speciality chemicals, these solutions are customisable and remain powerful even with frequent product changes.

We accompany and support you in the introduction of new exhaust air purification systems – from initial planning and documentation to maintenance and ensuring compliance with all current regulations such as TA Luft 2021 and IED.

By switching to modern, energy-efficient and certified exhaust air purification systems in good time, you can ensure long-term legal certainty, achieve cost advantages and strengthen the trust of your customers and partners. Especially in the chemical industry, where sustainability and compliance are becoming increasingly important, this will give you a decisive edge over your competitors.

Contact experts in exhaust air purification in the chemical industry and get advice

9. EXHAUST AIR PURIFICATION SOLUTION FOR PAINT SHOPS AND COATING COMPANIES – HOW MODERN EXHAUST AIR PURIFICATION INCREASES COMPETITIVENESS

The paint and coating industry has very specific requirements when it comes to exhaust air purification. In typical production environments – such as automotive supply, furniture manufacturing or metal finishing large quantities of volatile organic compounds (VOCs) and solvents are produced. These substances are released into the air during the actual coating process as well as during drying, cleaning and maintenance processes. In addition, aerosols, fine paint particles and unpleasant odours are produced, which increase the burden on employees and the environment, especially in closed production areas. In many cases, explosive atmospheres can also occur, especially when working with solvent-based paints.

The variety and quantity of pollutants vary depending on the industry and application. While in the automotive industry, the strict requirements of OEMs and authorities as well as high production volumes play a major role, in the furniture and metal industries, it is often changing batches, different coating systems and, in some cases, smaller companies that nevertheless emit significant amounts of VOCs. It is not uncommon for these companies to exceed the threshold of 5 tonnes of VOC emissions per year and thus be subject to the VOC Directive, which entails additional technical and administrative requirements.

Increasingly stringent legal requirements such as TA Luft, the European Industrial Emissions Directive (IED) and local regulations are putting pressure on companies in the painting and coating industry to take action. They must record all emissions and provide complete proof and documentation of their compliance. These requirements are regularly checked, particularly in the context of approval and renewal procedures for existing plants. Failure to meet the requirements may result in official sanctions, fines or, in the worst case, restrictions on production operations.

Another problem for many companies arises from the use of outdated technology. Many companies, for example in the automotive supply, furniture industry or metal finishing sectors, reach their limits when it comes to exhaust air purification if they are still using older technology. Classic thermal afterburning systems in particular are often no longer suitable for the large quantities of solvents (VOCs) produced today. They require a lot of energy, cause permanently high operating costs and are difficult to adapt to changing production conditions. This is becoming an increasing problem, especially for small and medium-sized enterprises, which are also under pressure from OEMs or local authorities.

Additional pressure to act is created by the increasingly stringent requirements of the TA Luft (Technical Instructions on Air Quality Control) and local approval authorities. As soon as more than 5 tonnes of VOCs are emitted per year, stricter requirements of the VOC Directive apply, which oblige companies to record and document everything without exception. At the latest when renewing permits for existing paint shops, upcoming audits or planned modernisations, it becomes clear that existing systems are often no longer sufficient.

The integration of compact, energy-efficient catalytic systems offers a modern solution. These systems are specially designed for high VOC loads and can be seamlessly integrated into existing processes – an ideal retrofit option for meeting all requirements at short notice. Compared to thermal systems, they reduce energy consumption and, thanks to their modular design and high flexibility, also offer decisive advantages for changing coating systems and production volumes.

We are here to advise you so that we can work together to achieve your goals – clean air, economical operation and full legal compliance. We accompany you every step of the way: from targeted analysis to ensure compliance with the VOC Directive, through planning and retrofitting, to conversion to energy-optimised catalytic systems. In this way, we ensure that you achieve long-term legal certainty, reduce your operating costs in the long term and strengthen your competitiveness – with a solution that underlines your commitment to sustainability.

Contact experts in industrial exhaust air purification and get advice

10. TAILOR-MADE EXHAUST AIR PURIFICATION SOLUTIONS FOR THE PRINTING INDUSTRY

(GRAPHOTYPOGRAPHY, FLEXOGRAPHY)

The requirements for exhaust air purification in the printing industry have increased significantly in recent years. Packaging printers, manufacturers of flexible packaging and label printers in particular are faced with the challenge of safely and efficiently removing large quantities of solvent-based emissions (VOCs) from their production processes. These pollutants originate both from the actual printing process and from cleaning and drying processes. VOC pollution is particularly high in indoor production lines, posing a risk to the environment and employees.

The increasing complexity of emissions requires tailor-made solutions from companies. While gravure and flexographic printing generate particularly high levels of VOCs, the requirements vary depending on the product and the printing ink used. In addition, different production volumes and changing order situations make it necessary to adapt the exhaust air purification system flexibly. The following applies to all sub-areas: reliable emission control is the basis for trouble-free and legally compliant operation.

External regulations such as the VOC Directive (2010/75/EU) are putting additional pressure on companies to take action. Authorities are demanding proof of compliance with limit values, and customers are increasingly expecting solutions that meet sustainability (ESG) requirements. Failure to comply with legal requirements can result in serious restrictions on business operations and heavy penalties imposed by the authorities.

Many companies also still work with outdated technology or inefficient cleaning systems. These consume an unnecessary amount of energy and lead to rising operating costs. Against the backdrop of rising energy costs and the trend towards greater sustainability in particular, companies can quickly find themselves at an economic disadvantage.

Modern, tailor-made exhaust air purification systems offer both economic and ecological advantages for companies in the printing industry. For example, catalytic systems with integrated heat recovery reliably reduce VOC emissions and energy consumption. Combined system solutions also enable the recovery of solvents and the intelligent use of waste heat. These technologies can be flexibly adapted to different production profiles and pollutant quantities and help companies to reliably comply with all legal requirements.

Thanks to our experience, we understand your challenges and work with you to develop a customised exhaust air purification solution.

From the initial analysis, profitability calculation and planning to implementation and regular maintenance, we accompany you step by step throughout the entire project. In doing so, we place particular emphasis on ensuring compliance with the requirements of the VOC Directive, enabling seamless documentation for audits and optimally integrating your exhaust air purification into your company's sustainability strategy.

With us at your side, you can be sure that all technical, economic and legal requirements will be implemented professionally. Together, we will lay the foundation for long-term legal certainty and reduced operating costs.

Contact experts in exhaust air purification in the printing industry and get advice

11. EXHAUST AIR PURIFICATION SOLUTION FOR THE PHARMACEUTICAL INDUSTRY: FUTURE-PROOF AND AUDIT-COMPLIANT – HOW PHARMACEUTICAL COMPANIES ARE MEETING ENVIRONMENTAL REGULATIONS

Pharmaceutical manufacturing processes produce emission mixtures that contain organic substances as well as unpleasant odours and, in some cases, toxic or reactive components. This exhaust air comes from various production areas: from synthesis plants and solid production to cleaning and safety extraction systems. Each of these sources has its own requirements for exhaust air purification technology.

Requirements are increasing, particularly due to the high regulatory standards in the industry. Pharmaceutical companies must comply with national laws such as the Federal Immission Control Act (BImSchG), as well as international guidelines and specific environmental regulations such as those of the FDA (Food and Drug Administration) and the EMA (European Medicines Agency). In addition, Good Manufacturing Practice (GMP) and the often necessary validation and complete documentation of exhaust air purification require the highest level of process reliability. By complying with the complex requirements and specifications as well as the limit values, companies avoid high avoidable fines.

In areas involving synthesis processes or solid production in particular, emissions are often so complex that standard solutions quickly reach their limits. The pressure to act is also increasing noticeably when new production lines are planned, audits are pending or approval procedures under the Federal Immission Control Act (BImSchG) have to be prepared. The shift towards greater sustainability is also forcing pharmaceutical companies to rethink their exhaust air concepts. Validatable and documentable cleaning systems are therefore increasingly becoming a central component of quality management and approval security. This is particularly relevant for air purification as part of clean room technology or exhaust gas flows from safety extraction systems.

Powerful and validatable cleaning systems are the answer to these challenges. With highly efficient filtration, adsorption or catalytic systems, a wide variety of emission mixtures can be safely controlled and tailored precisely to your needs. These systems are designed to be easy to validate, fully documentable and seamlessly integrated into existing quality and safety concepts. The result: you will meet legal requirements and GMP specifications and benefit from lower operating costs, greater process reliability and greater flexibility in everyday operations.

We are at your side as a reliable partner every step of the way – from analysis and planning to support with approval procedures to implementation and ongoing maintenance of your exhaust air purification system. Together, we develop a concept that is precisely tailored to your processes and will remain audit- and approval-compliant in the future.

Contact experts in exhaust air purification in the pharmaceutical industry and seek advice

12. ODOUR ELIMINATION FOR ROASTERS AND PROCESSORS: MODERN EXHAUST AIR PURIFICATION SOLUTIONS FOR THE FOOD INDUSTRY

In the food industry, many production steps release strong odours and organic compounds. The composition of the exhaust air in these companies is often characterised by volatile organic substances and odour carriers. For example, roasting plants release high quantities of odour-active substances. Spice processors and manufacturers of instant products, on the other hand, often release fine aromatic components into the air. Particularly in production facilities with high levels of odour-intensive emissions, such as large-scale roasters of coffee, cocoa and nuts, as well as manufacturers of spices and instant products, complaints from the neighbourhood are a regular occurrence, leading to increasing pressure to obtain permits.

At the same time, legal requirements are becoming stricter, for example through strict odour emission guidelines such as the GIRL (Odour Emission Guideline). This means that the companies affected are obliged to use effective and efficient exhaust air purification solutions in order to comply with environmental regulations and protect the economic interests of the company – for example, by protecting against possible lawsuits from residents.

These specific requirements pose particular challenges for exhaust air purification: the aim is to reliably reduce odours and pollutants without disrupting ongoing operations, while at the same time strengthening the economic efficiency of companies in the food industry through low energy costs.

Outdated exhaust air systems are becoming an increasing problem. Many conventional oxidation systems work exclusively with thermal afterburning, which leads to high gas consumption, constantly rising operating costs and an unfavourable carbon footprint. Companies that fail to modernise their exhaust air systems risk falling behind their competitors and face ever-increasing cost pressure.

Innovative and modular systems for catalytic odour reduction provide an efficient and future-proof solution to these challenges. Compared to conventional thermal systems, they are significantly more energy-efficient and comply with all relevant legal requirements. They support you in meeting your documentation obligations and thus contribute to a sustainable reduction in operating and administrative costs.

To help you reap these benefits, we support you as an experienced provider from the analysis of your individual situation to the successful commissioning of tailor-made exhaust air purification solutions. Our service includes on-site assessment, selection of the optimal purification technologies and professional support throughout the entire approval process. Thanks to our numerous successful projects in the field of odour-sensitive applications, you will receive comprehensive, individual and practical advice from us. Please feel free to enquire about our reference projects.

Contact our specialists for exhaust air purification in the food industry and let us advise you

13. SMART EXHAUST AIR PURIFICATION SOLUTIONS FOR BIOGAS PLANTS, SEWAGE TREATMENT PLANTS AND THE WASTE MANAGEMENT INDUSTRY – WHY OPERATORS OF BIOGAS PLANTS, SEWAGE TREATMENT PLANTS AND THE WASTE MANAGEMENT INDUSTRY NEED TO ACT NOW

Municipal and private operators of biogas plants, sewage treatment plants and waste management companies are facing ever greater challenges in exhaust air purification. Requirements are becoming particularly stringent at sites with high emissions and strong odour nuisance: these sites are often already subject to strict regulatory requirements and a lack of public acceptance, which leads to increased protests.

The processes in the relevant plants typically produce pollutants such as ammonia (NH₃), hydrogen sulphide (H₂S), volatile organic compounds (VOCs) and odorous substances. These originate from different areas of production. Ammonia, for example, is a typical by-product of drying organic materials, while gas storage and composting mainly release VOCs and odorous substances into the exhaust air. The problems are exacerbated, especially at already polluted sites, when several sources of emissions come together.

The challenges vary depending on the application: In biogas plants, the focus is often on removing hydrogen sulphide and organic odours produced by the fermentation of biomass. Sewage treatment plants, on the other hand, face the task of reducing ammonia and VOC emissions from various treatment stages as well as odorous substances from drying plants.

However, one thing applies everywhere: emissions are a technical problem and are increasingly leading to acceptance issues among residents, citizens' initiatives and authorities. At the same time, external requirements are growing. The TA Luft (Technical Instructions on Air Quality Control) and the Federal Immission Control Act (BImSchG) set clear limits for pollutants such as NH₃, H₂S and VOCs, and compliance is being monitored more strictly. This is putting companies under pressure to act. Economic interests also come into play: energy-intensive exhaust air purification systems increase operating costs as energy prices rise and reduce competitiveness. Those who hesitate to modernise therefore run the risk of suffering a permanent competitive disadvantage.

Action becomes imperative at the latest when new legal requirements have to be implemented or complaints from the neighbourhood increase. In many cases, requirements are already part of the operating licence. Companies are then forced to present viable solutions at short notice – ideally before acceptance problems or official requirements further restrict their scope for action.

This is where innovative low-temperature exhaust air purification processes come into play, which have been specifically developed for the requirements of the waste management industry. These systems are characterised by low energy consumption, high reliability and low maintenance costs. They can be flexibly adapted to the respective pollutant profiles and achieve excellent results even with complex emissions from drying, gas storage and composting. This results in enormous advantages for operators: significantly reduced operating costs, lower energy consumption, simpler maintenance and a better starting position with authorities and subsidy applications. At the same time, you make an active contribution to social acceptance, as odours and pollutants are effectively eliminated.

With the right partner, you can reduce your costs, increase public acceptance of your plant and reliably comply with specifications and regulations. We work with you as a long-term partner, from analysing your current situation and selecting and implementing the right exhaust air concepts to installing, maintaining and monitoring exhaust air purification systems.

Get advice from experts in smart exhaust air purification solutions for biogas plants, sewage treatment plants and the waste management industry – for greater acceptance, lower costs and a sustainable future.

14. FROM PROJECT LAUNCH TO CONTINUOUS OPERATION: EXHAUST AIR PURIFICATION AS A SUCCESS FACTOR IN BATTERY AND SEMICONDUCTOR PRODUCTION

The expansion of battery and semiconductor production in Europe poses considerable challenges for companies in terms of exhaust air purification. With the construction of new gigafactories and cleanrooms, production capacities are growing rapidly – at the same time, the demands for effective emissions management are increasing. Operators, planners and investors of new sites in particular are often confronted with the task of implementing safe, scalable and economically efficient solutions for the treatment of exhaust air and pollutants. The multitude of regulatory and technical requirements creates uncertainty and makes targeted support from a trusted partner and expert essential.

The high requirements for exhaust air purification are due to the reactive and toxic gases produced during the manufacturing process, such as hydrogen fluoride (HF) and various solvents. These emissions arise at different stages of production – from battery electrode manufacturing to lithography in semiconductor production. Applications in potentially explosive areas are particularly challenging, as they require not only emission reduction but also protection against operational risks. At the same time, companies are under increasing pressure to act due to new external regulations such as the EU Battery Regulation and compliance with ESG (environmental, social, governance) criteria. Anyone manufacturing in Europe must demonstrate that their production and products meet the highest sustainability and safety standards. Without appropriate exhaust air purification solutions, there is a risk of heavy fines, regulatory requirements and reputational damage. The diversity of emissions and their sources therefore calls for industry-specific solutions. Battery factories, for example, often need compact, robust systems that work reliably even when utilisation fluctuates. In semiconductor manufacturing, the highest standards of purity and safety are paramount, especially when handling aggressive process gases and solvents.

To overcome these challenges, it is crucial to use sustainable and scalable cleaning systems at the latest during the planning phase of a new site. Involving an experienced partner for exhaust air cleaning solutions at an early stage makes it possible to integrate tailor-made, individual solutions for filter and catalyst systems, thus establishing a consistent, sustainable production profile right from the start. Modern, highly efficient exhaust air purification systems offer flexibility and safety and impress with their modular design, minimal space requirements and easy scalability to reliably meet the complex requirements of battery and semiconductor manufacturing. The intelligent combination of filter systems, catalysts and precise gas monitoring makes it possible to reliably minimise the emission of critical substances – while maintaining high energy efficiency and thus low operating costs. This ensures that legal requirements are met and competitive advantages are created at the same time.

We accompany you from the initial project idea through detailed planning to implementation and subsequent optimisation of your exhaust air purification system. Our consulting approach includes a careful analysis of your specific requirements, leading to the selection of the optimal exhaust air purification technology and its smooth integration into existing or new production processes. This allows you to benefit from tailor-made exhaust air purification solutions that are tailored to your needs, meet all regulatory, economic and operational requirements, and make your location future-proof.

By working together as partners, you lay the foundation for a sustainable and economically successful production facility. Seize this opportunity now and benefit from our extensive experience and unique consulting services for battery and semiconductor manufacturers – together, we will find the optimal solution for you to make your exhaust air purification processes safe, efficient and sustainable.

15. EXHAUST AIR PURIFICATION FOR SOLVENTS – HOW TO SUSTAINABLY AND EFFICIENTLY MANAGE SOLVENT EMISSIONS IN YOUR OPERATIONS

Whether in paint shops, coating companies or chemical production facilities – wherever solvents are processed, companies face particular challenges when it comes to exhaust air purification. Solvents cause unpleasant odours and health hazards in the workplace. They also increase safety risks. Volatile organic compounds (VOCs) are often highly flammable or even explosive. That is why strict limits such as AGW (occupational exposure limit) and MAK (maximum workplace concentration) apply in the workplace to ensure the protection of employees and the environment.

Damage to reputation and increased sick leave are real dangers associated with inadequate exhaust air purification. Companies that fail to take proactive action in good time expose themselves to high risks – from costly regulations and fines to the possible shutdown of operations.

From an economic perspective, inadequate solvent purification is also disadvantageous. Valuable solvents are lost unused when they escape into the exhaust air, and if heat recovery remains unused, energy and operating costs increase. This has a particularly negative impact on operating results, especially in times of rising energy prices and stricter CO₂ regulations.

Proof of effective emission reduction is also becoming increasingly important, as authorities and auditors are increasingly demanding complete documentation. This creates additional pressure to act, especially when processes are changed or new requirements are introduced.

The right solution for these diverse challenges are modern exhaust air purification systems that have been specially developed for handling solvents. Catalytic or adsorptive processes remove VOCs safely and efficiently, while special filters also provide effective odour neutralisation. Thanks to integrated heat recovery, these systems can significantly reduce operating costs and, if necessary, recover valuable solvents for reuse in the production process. These technologies also provide maximum safety and reduce the risk of explosion through proven plant technology – and can be seamlessly integrated into existing processes, such as painting or coating systems.

We understand that every industry and every business has its own requirements. That's why we support you from the initial assessment, through consultation, selection and integration of the optimal exhaust air purification systems, to commissioning, maintenance and regular monitoring. We support you in proving effectiveness to authorities and help you document your exhaust air purification solution in such a way that you can complete audits in compliance with legal requirements. Together, we create an environment in which health, economy and sustainability are in harmony.

A modern exhaust air purification solution for solvents offers you numerous advantages: you ensure healthy, safe working conditions, save energy and raw materials, comply with all legal requirements and strengthen your position as a sustainable, responsible company. Contact us and we will work with you to develop the right solution to keep your business safe, sustainable and successful.

Contact our experts for sustainable reduction of solvents in exhaust air and let us advise you

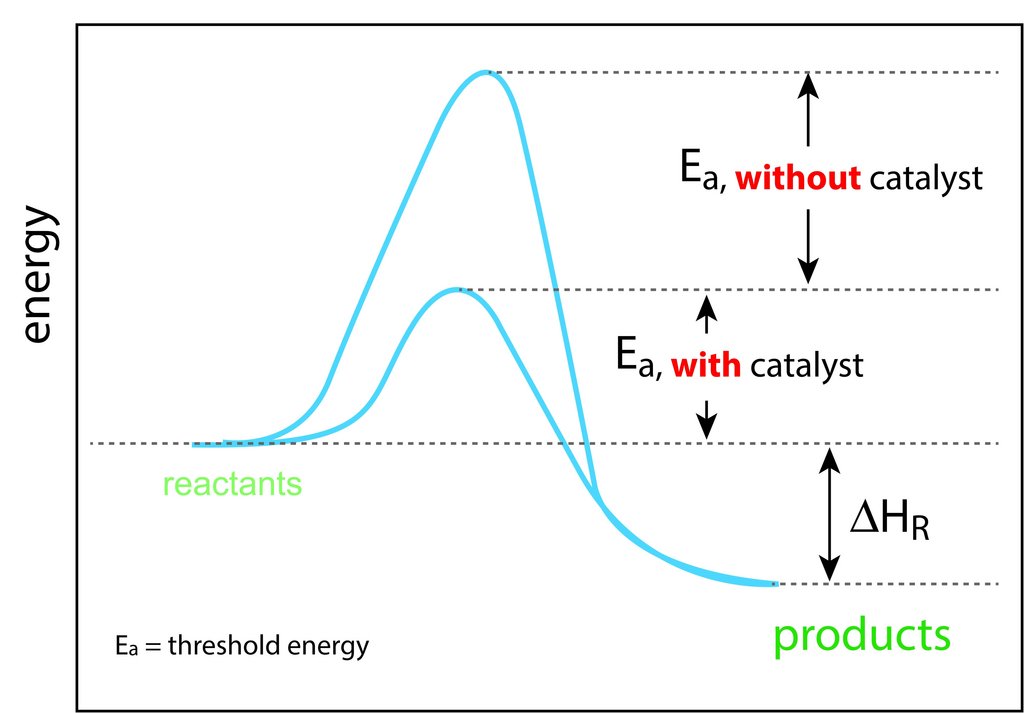

In colloquially referred to as catalytic post-combustion, organic pollutants (such as VOCs) are oxidised into harmless gases at comparatively low temperatures with the aid of a catalyst. The term combustion is somewhat misleading here, as the pollutants are not simply burned. Catalytic oxidation requires significantly less energy than conventional thermal systems. CatOx systems are therefore characterised by high energy efficiency and low operating costs – especially with large volume flows. They are ideal for processes in which large quantities of easily oxidisable pollutants are regularly produced, such as in the chemical, pharmaceutical or coating industries.

In adsorption processes, pollutants are bound to the surface of solids such as activated carbon or zeolite. Adsorption processes are particularly suitable for removing solvents and odours and are highly effective even at low pollutant concentrations. These systems clean the primary air flow at room temperature, thereby requiring even less energy. The major advantage is that desorption takes place in parallel with the actual purification process in a significantly smaller air flow, which can then be purified effectively and efficiently. This means that these processes can be flexibly combined with other purification technologies, making them versatile for use in various industries such as printing, painting and food production.

Ozone treatment relies on the powerful oxidising effect of ozone, which destroys organic pollutants and, above all, odours. The process does not produce any residues, meaning that no filter changes or similar measures are necessary. Ozone is produced automatically during operation, which makes it particularly easy to use. The method is effective against VOCs and odours and can be optimally combined with other exhaust air purification processes – ideal for industries where flexibility and continuous operation are required.

Would you like to know which technology suits your processes?

a. Our responsibility xpuris technology for exhaust air purification is a win-win situation for everyone

Not only increasing global traffic, but above all industrial emissions are responsible for the steady rise in emissions. In recent years, these have significantly deteriorated air quality in many regions of the world. It is time to take responsibility. Only by working together to protect people, animals and the environment can we protect our climate and ultimately our planet.

Clean air means better health, an intact environment and a livable future for generations to come. This future depends on how we face up to our responsibility for our environment and air quality now. At xpuris, we support your company in removing microparticles, fine dust, VOCs, nitrogen oxides, greenhouse gases and other production-related pollutants from your exhaust air and improving air quality in the long term.

It is entirely up to us whether we view air pollution control as a chore or as an opportunity to bring about positive change. It is time we took air pollution seriously and did our utmost to ensure clean air for all – for a healthier, sustainable and prosperous future, together, for all of us.

xpuris supports you with innovative technology and state-of-the-art exhaust air purification systems to bring about positive change together.

Customised solutions for sustainable exhaust air purification

b. Discover how tailor-made high-tech solutions can clean your exhaust air – and make your company fit for the future!

Every industrial production process brings its own challenges when it comes to exhaust air purification. At xpuris, we therefore rely on comprehensive consulting, detailed analysis and precise engineering to create solutions that are precisely tailored to your production reality. From the initial assessment and detailed analysis of the current situation to the development and manufacture of a tailor-made system concept, right through to turnkey commissioning and ongoing maintenance, we accompany you through all phases of the project. Our goal is to optimally cover your exhaust air flows and operational requirements at all times and to create a sustainable solution for your business.

We combine state-of-the-art processes such as catalytic oxidation, UV treatment and adsorption. Our systems can be equipped with customised catalysts, innovative concentration solutions and efficient heat recovery for maximum energy efficiency. This enables you to achieve maximum energy efficiency and a fast return on investment – even with highly fluctuating processes and emissions or frequent product changes.

Thanks to our modular system design, we offer the right solution for every system size and volume flow – from the first pilot project to large-scale systems for continuous operation. Our proven technologies such as ACP (Advanced Catalytic Purifier), UVP (Ultraviolet Purifier), AWP (Adsorption Wheel Purifier), FBP (Fluidised Bed Purifier) and our xpuriCAT catalysts are continuously being further developed and can be flexibly combined to meet your requirements. Digital process monitoring, remote maintenance and, on request, a reliable 24/7 service ensure maximum operational reliability.

At the same time, you benefit from our comprehensive transfer of knowledge: through targeted training and ongoing know-how sharing, we enable you to manage your facilities independently and sustainably. Close collaboration throughout all project phases makes you self-reliant and establishes the foundation for long-term success.

Our customised exhaust air purification systems are individually designed for every industry, production volume and pollutant profile – whether you are dealing with large or small amounts of VOCs, ammonia, nitrogen oxides, or odorous substances such as those typically occurring in food processing. From traditional chemical plants, the pharmaceutical, printing or coating industry, to highly specialised production lines: we always provide you with the optimal solution, precisely tailored to your requirements.

With an exhaust air purification system from xpuris, you reliably comply with all legal requirements, such as TA Luft, IED or industry-specific regulations, while at the same time benefiting from economic advantages. These include lower operating costs, significant energy savings and a flexibly adaptable system architecture that can be seamlessly integrated into existing production processes. The documented effectiveness of our technologies also facilitates audits and approvals.

In this way, you create clean air for employees, local residents and the environment, strengthen your competitiveness and corporate image – and secure a sustainable, future-proof position in the market.

-

I. ACP - Catalytic exhaust air purification

In many industries, the safe and economical removal of organic pollutants from exhaust air is a challenge. ACP systems efficiently convert harmful VOCs into harmless gases at low temperatures, enabling maximum purification performance. The integration of heat recovery significantly reduces operating costs, while all-electric operation reduces CO₂ emissions. Thanks to its compact, modular design, the system is quick to install and flexible to use.

The result: Over 99.9% pollutant removal, up to 85% heat recovery with maximum energy efficiency, fast installation, and safe, legally compliant operation with a low environmental footprint.

Find out more - Catalytic exhaust air purification: highly efficient technology proven for decades

-

II. UVP - UV cleaning

Conventional exhaust air purification systems reach their limits, especially in temperature-sensitive processes or with low to medium pollutant concentrations. UVP systems destroy organic molecules and odorous substances using high-energy UV light and are particularly effective against VOCs and odors. Operation is fully electric and low-maintenance; the systems are modular and can be installed centrally or decentrally. Automated self-cleaning guarantees trouble-free continuous operation. UVP systems thus offer a cost-effective, flexible, and future-proof solution.

-

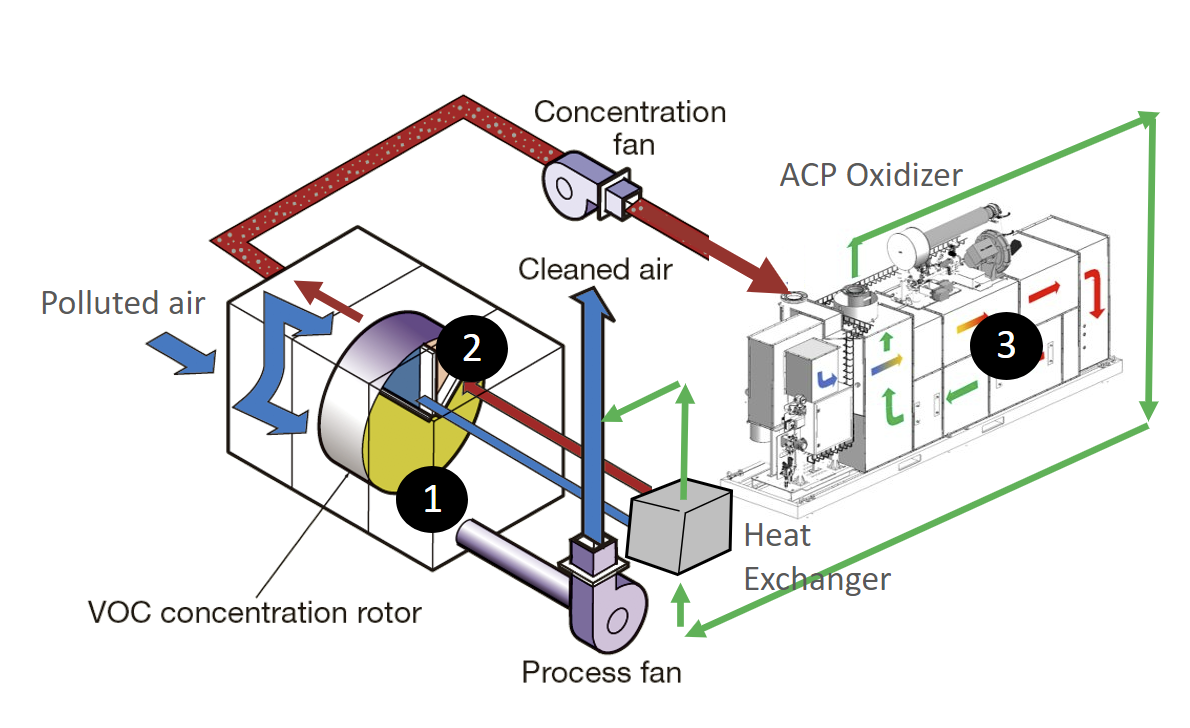

III. AWP - Adsorption rotor

Many companies face the challenge of reliably removing VOCs, solvents, and odors from changing exhaust air streams on a long-term basis. The AWP process uses rotating adsorbers that intelligently combine adsorption and catalytic purification, thus achieving particularly high purification performance. Thanks to the continuous concentration separation of VOCs, the system can be operated extremely energy-efficiently at low temperatures. The rotor modules used are impressively robust and durable, requiring little maintenance. Furthermore, pre-assembled, individually adapted modules ensure quick installation and consistently reliable operation.

Find out more about the combination of adsorption on a zeolite rotor and catalytic oxidation

-

IV. FBP – Fluidized – Bed – Purifier

Highly fluctuating and highly contaminated exhaust air streams often pose major challenges for companies. The FBP system uses an energy-efficient activated carbon fluidized bed, achieving maximum purification efficiency even in the most demanding and heavily contaminated exhaust air streams. This technology ensures effective removal of pollutants without leaving residues, especially in highly contaminated processes. The system is scalable and modular, allowing it to adapt flexibly to varying volume flows and changing production processes. Thanks to all-electric operation, simple operation, and a maintenance-friendly design, operation remains trouble-free, while our comprehensive service and reliable spare parts supply ensure consistently high system availability. lith rotor and catalytic oxidation.

Find out now - How exhaust air purification works using the fluidized bed process

-

xpuriCAT – Catalysts

Many companies face the challenge of cleaning complex exhaust air mixtures where standard solutions reach their limits – especially when very different pollutants must be removed simultaneously. Our specially developed catalysts are tailored precisely to such requirements. They offer maximum efficiency, an exceptionally long service life, and impress with certified quality and verifiable results thanks to continuous monitoring.

To identify the best possible catalysts for your needs, we conduct feasibility studies on-site using mobile test systems. This also determines whether the need is temporary or permanent. Based on the analysis findings, we then support you with our complete package, from detailed planning through installation and commissioning to service and maintenance. Our catalysts are also distinguished by their dual function, allowing them to degrade various pollutants in parallel.

Our technology combines engineering and chemical expertise at the highest level and guarantees reliable purification performance with continuous quality control. This provides you with a safe, high-performance, and sustainable exhaust air purification solution – ensuring stable, legally compliant operation over the long term.

Discover customized exhaust air purification solutions for your business – learn more now.

- Advantages of our services at a glance

- Guarantee of cleaning efficiency over specified periods

- Easily convertible systems from gas to electric heating thanks to modular design

- Project support from A to Z by experienced experts

- 360° consulting, planning and documentation

We support you from the initial analysis to the commissioning of your exhaust air purification system. Your dedicated contact ensures smooth processes, customized planning, and comprehensive, legally compliant documentation.- Comprehensive project consulting from analysis to commissioning

- Personal contact person for the entire project duration

- Individual and tailor-made plant planning

- 3D planning and realistic simulation

- Turnkey solutions from a single source

- Employee training and know-how transfer

- Legally compliant documentation and evidence for authorities

- 100% implementation, monitoring & spare parts supply

We take care of the complete implementation, operation, and monitoring of your exhaust air purification system. With state-of-the-art technology, automated monitoring, and rapid spare parts delivery, we ensure maximum efficiency and minimal downtime.- Selection and integration of the optimal cleaning technology (e.g. catalytic, UV, adsorption)

- Use of modern and energy-efficient processes

- Integration of heat recovery

- Fully automated plant control and monitoring

- Maintenance and repair by trained specialists

- Fast and reliable supply of spare parts

- Scalable

Our solutions grow with your requirements – from small pilot projects to large-scale plants in continuous operation. Thanks to our modular system architecture, you can respond flexibly to changing production conditions and future expansions.- Scalable systems for every company size

- Flexible adaptation to changing production requirements

- Expansion options for future growth

- 24/7 Service and Support Hotline: With our 24/7 service and support hotline, we're available to you at any time. This ensures maximum operational reliability and prompt support for all your concerns.

Our experts comprehensively analyze your exhaust air situation and develop individual concepts for maximum efficiency and legal certainty.

- Holistic analysis of the exhaust air situation on site (pollutant types, volume flows, process conditions)

- Development of tailor-made plant concepts according to legal requirements (e.g. TA Luft, BImSchV) and feasibility analysis

- Preparation of economic benefit and profitability assessments - We calculate total cost of ownership (TCO) taking into account investment costs (CAPEX) and operating costs (OPEX)

We design and construct tailor-made systems, perfectly tailored to your operational requirements.

- Individual coordination: Joint definition of all specific requirements and boundary conditions based on your production.

- Basic Engineering: Definition of temperature and pressure profiles as well as specification of all core processes, components, sensors and actuators.

- Detailed Engineering: Creation of models, manufacturing drawings, P&I diagrams and electrical wiring diagrams including complete documentation.

- Factory Acceptance Test (FAT): Comprehensive testing and documentation of the system before delivery – including functional, leak, and safety tests.

- Smooth commissioning training: Professional installation and commissioning on site as well as instruction and training of your employees.

Find out more about our engineering services and our individual plant design

We record and evaluate the current exhaust air quality in order to identify targeted optimization potential.

- Process definition and visualization: Precise recording and graphical representation of all process sequences, definition of the relevant measuring points and measurement characteristics.

- Analysis of the production program: Examination of all production modes and materials used, adapted to different production processes.

- Exhaust gas composition and process gas recipes: Calculation of the expected exhaust gas compositions per measuring point and compilation of all technical data sheets.

- Individual measurement plan: Development of a specific measurement plan for each production mode with selection of suitable measuring instruments and definition of all measurement tasks.

- Measurements: Continuous online measurements and spot sampling using modern analytical methods (e.g., FID, analysis for benzene, phenol, amines, formaldehyde).

- Comprehensive documentation: consolidation, evaluation, and transparent reporting of all measurement results, including all protocols for verification purposes.

Achieve greater efficiency through professional exhaust air measurement – find out more here

We use mobile test systems to test your optimal solution under real operating conditions before you invest.

- Analysis of processes and compilation of all relevant information

- Recording of all production modes and input materials including limit values

- Calculation of the raw gas composition for each operating condition

- Creation of a detailed test plan with time and measurement tasks

- Planning and adaptation of the test facility including core components

- Manufacturing or conversion of the test system, including programming and documentation

- Commissioning of the test system on site or via remote instructions

- Carrying out exhaust air purification tests and emission measurements, flexibly as required

- Evaluation, reporting and presentation of all results

Find out more about our engineering services and our individual plant design

We train your team to operate your plant safely, efficiently, and in compliance with legal requirements.

- Communication of the procedure, functional relationships and necessity of the exhaust air purification system

- Detailed instruction on operation, components, monitoring and documentation tasks

- Training in maintenance, troubleshooting and independent maintenance

- Completion with full training certificate for your company

Our reliable spare parts logistics ensures that your system always remains operational.

- An individual spare parts list is created during the engineering process and updated regularly.

- Spare parts are ordered early and delivered to your maintenance warehouse on time – just-in-time to avoid bottlenecks.

- Used spare parts are replenished according to the “first in – first out” principle to ensure that we always have an up-to-date inventory.

- Fast reordering and delivery ensures the continuous smooth and safe operation of your exhaust air purification system.

With the ACP system, we provide a modular, electric solution for VOC exhaust air purification that catalytically converts pollutants into harmless gases, reducing energy consumption and CO₂ emissions. The benefits for you are:

- Over 99.9% reduction of VOC emissions

- No harmful by-products or waste

- Autothermal operation possible at high emission load

- Fully electric standard operation available

- Compact, modular design

- Systems are assembled and tested before delivery

- Plugand Play solutions for quick commissioning

- Short delivery times for standard versions

Arrange a consultation with experts – for an efficient and sustainable exhaust air solution

The xpuris UVP system uses UV photooxidation to remove VOCs and odors from large airflows with low pollutant loads in an energy-efficient, electrically operated, and modular manner. The benefits for you are:

- Cleaning large air flows with low emissions

- Low energy consumption and minimal pressure loss

- Automatic lamp cleaning for long life

- Fully electric without warm-up phases, high availability

- Dimmable version also for higher exhaust air temperatures

- Compact, modular design – space-saving

- Short delivery times for standard modules

- Minimal maintenance, reliable operation

To the UVP portfolio for clean and odor-neutral air

Your path to clean air begins with expert advice – fill out the form now and get advice